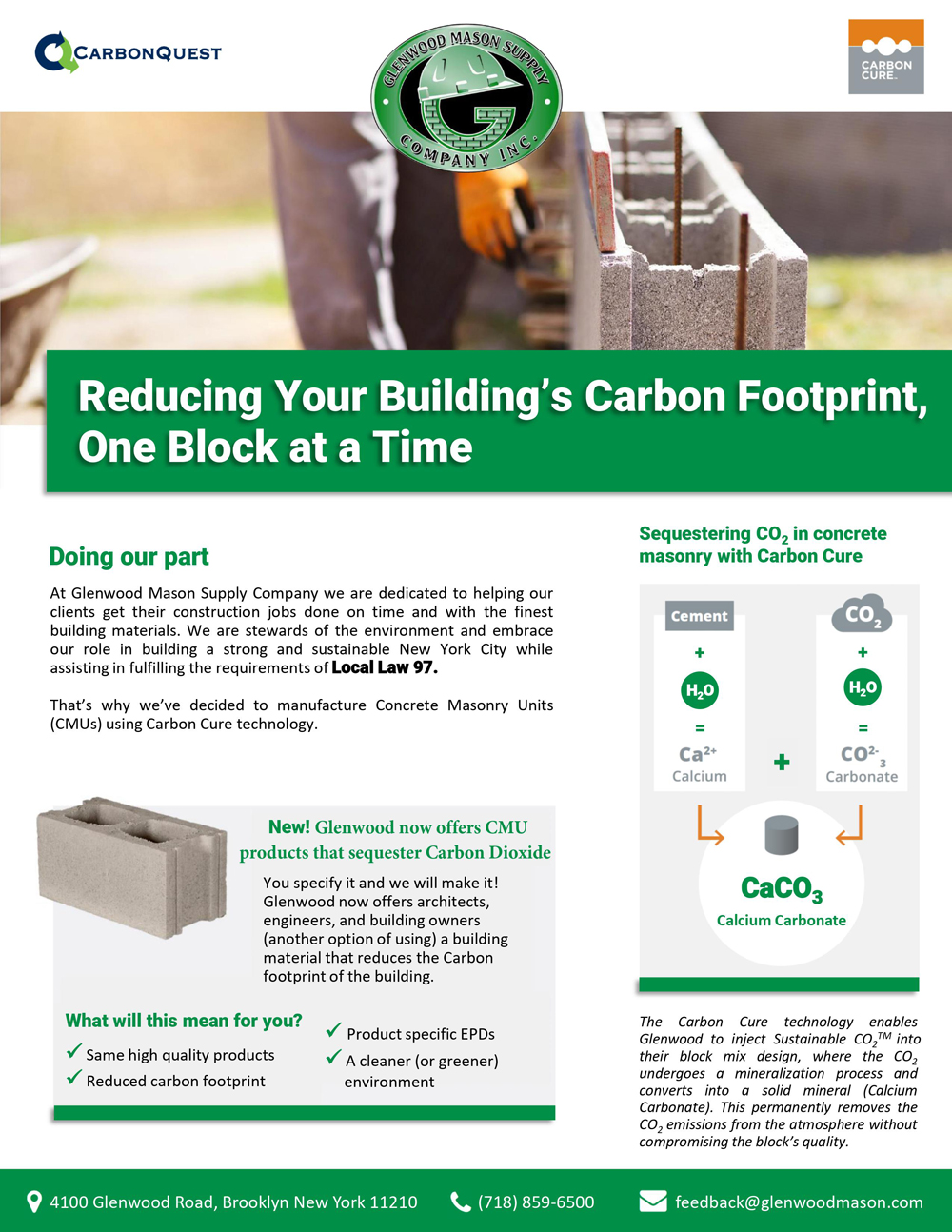

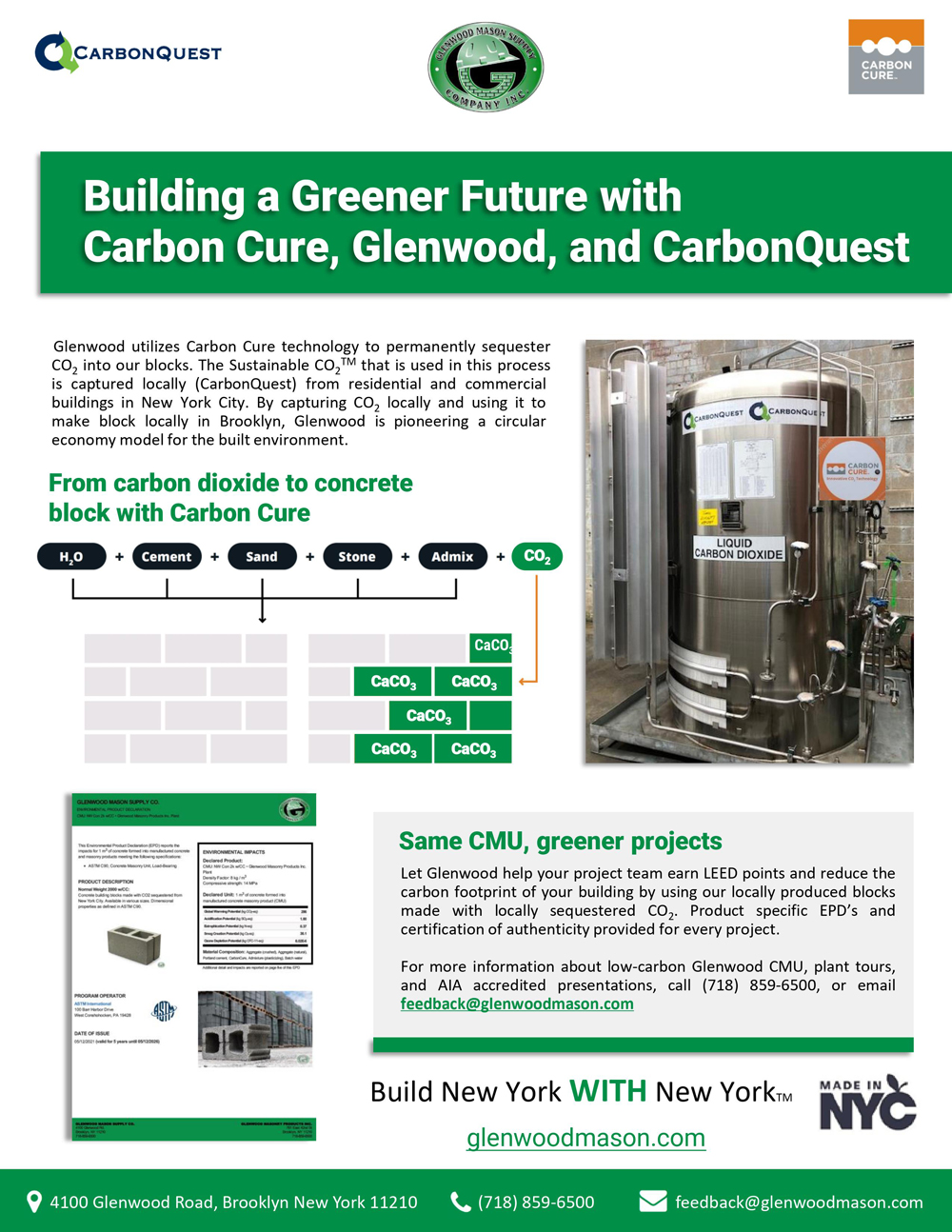

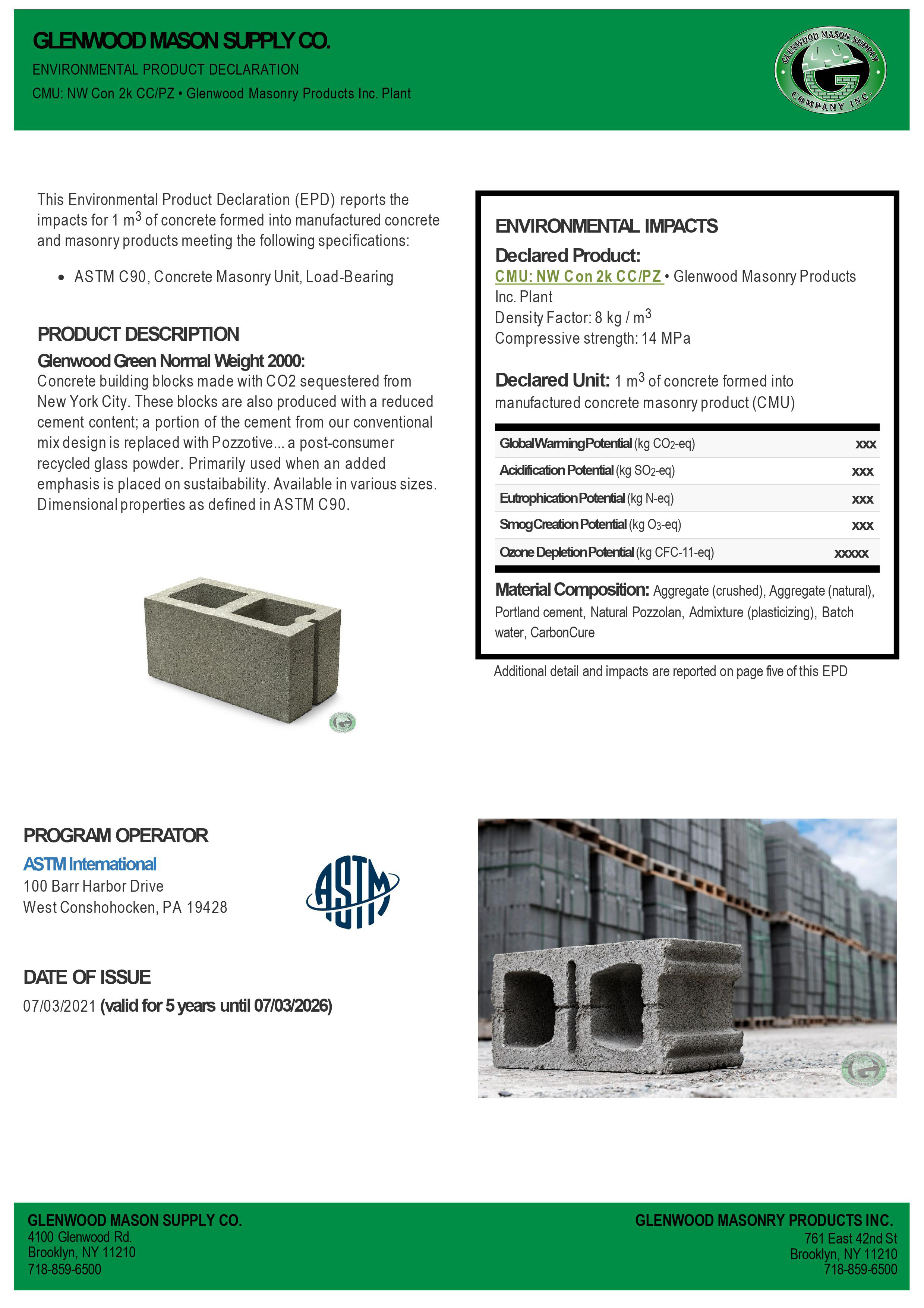

- Concrete block containing sequestered carbon dioxide

- Controlled mix designs to ensure consistent carbon contribution per block

- Available in every size regular CMU is offered

- Only CMU producer in New York equipped with Carbon Cure™

GLENWOOD GREEN INITIATIVE

sustainable. smart. solutions.

Mission Statement

"At Glenwood, we are committed to achieving the highest level of sustainability on your project, while keeping a close eye on your budget. We are committed to helping our clients design a beautiful, safe, sustainable world."